What is Auger Spectroscopy?

Auger Electron Spectroscopy (AES) is named after the French physicist Pierre Auger who was given credit in the mid-1920s for discovering the effect where an inner-shell vacancy of an atom is accompanied by the emission of an electron from the same atom.

Now known as the Auger Effect, this phenomenon was first developed into commercial Auger spectrometers in the 1960s and evolved from simple TFA (thin film analyzers) to the high spatial resolution scanning Auger spectrometers that are available today.

How does it work?

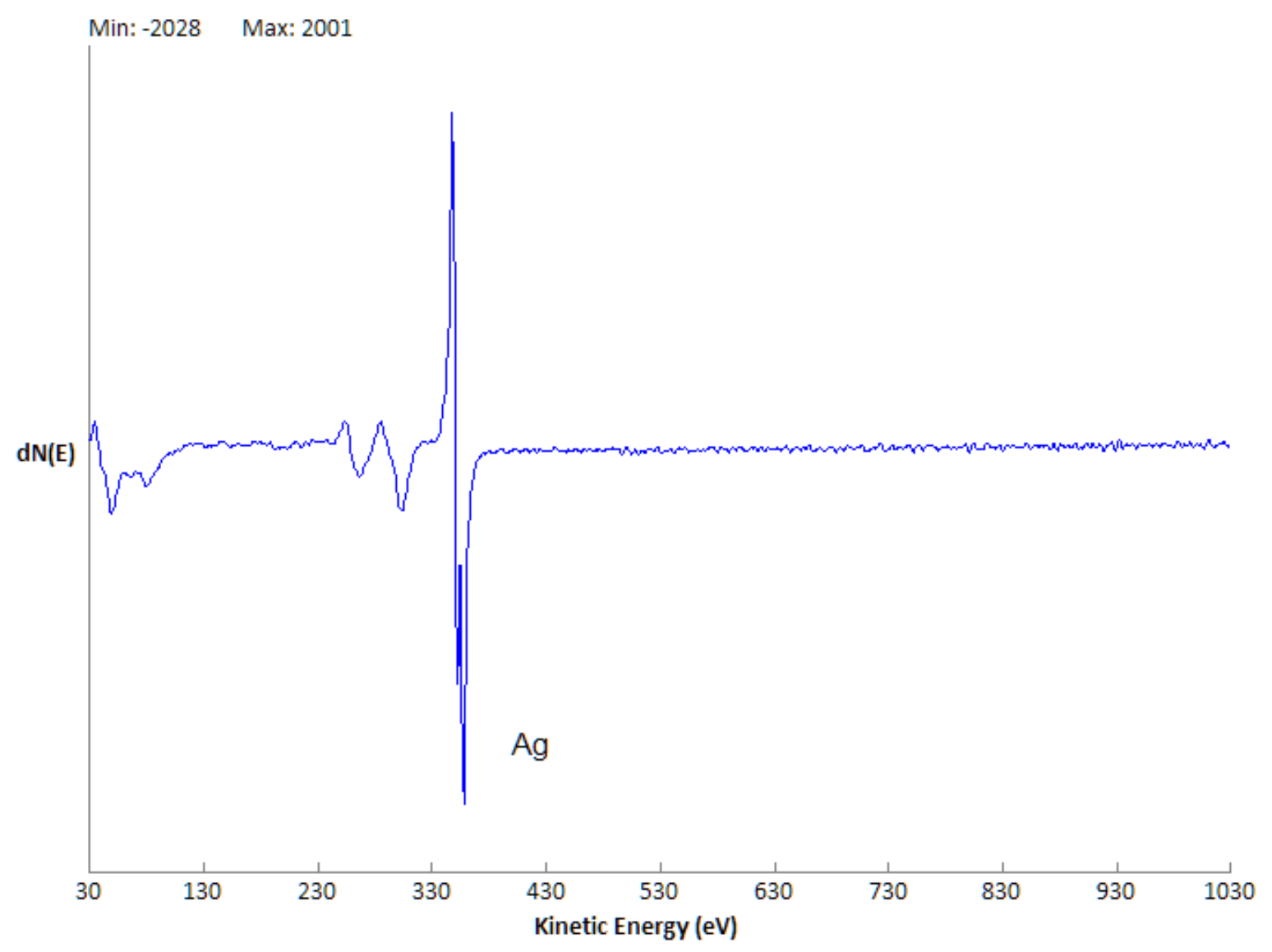

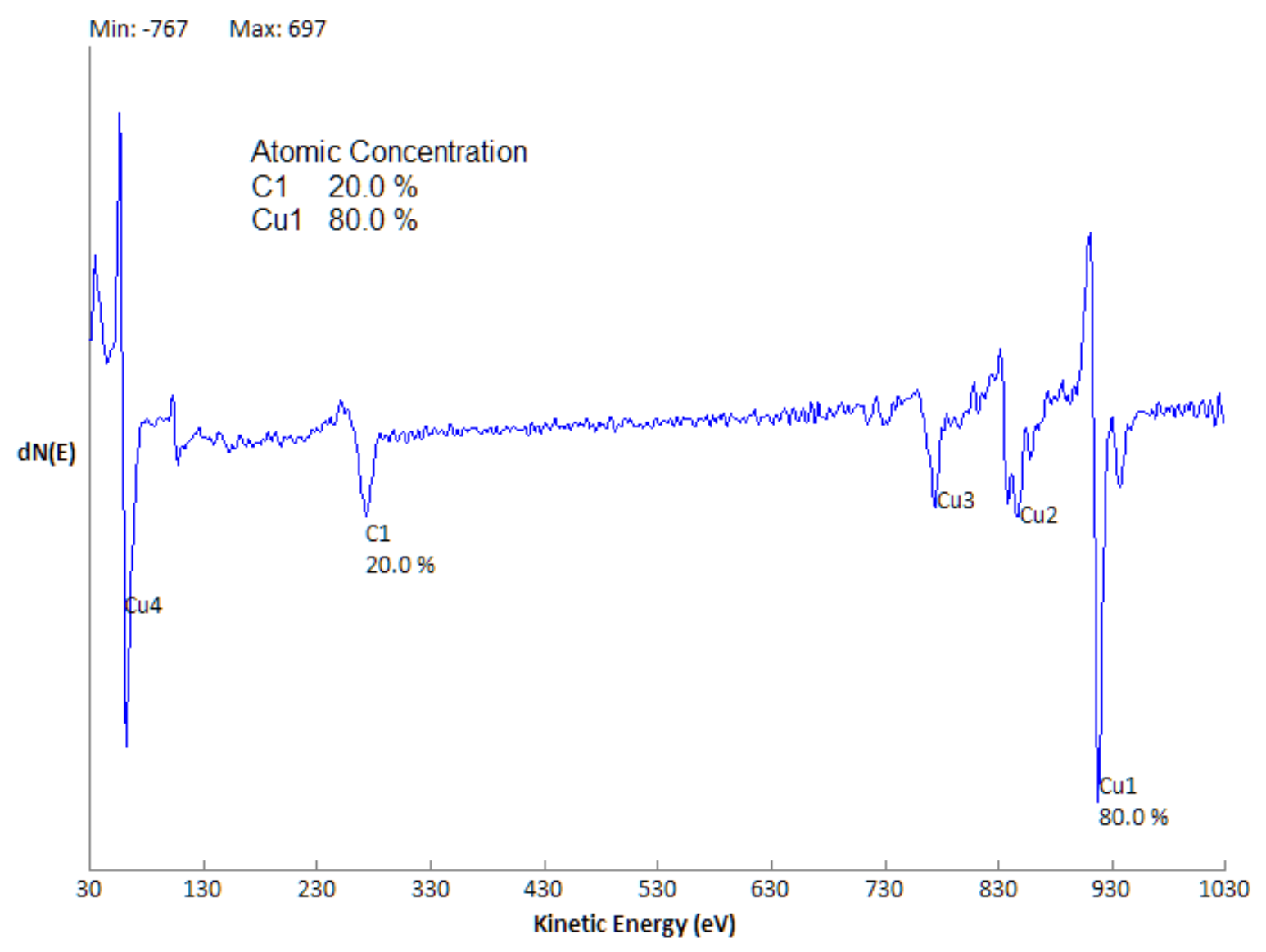

A fine electron beam with an energy of typically 3 kV to 20 kV is used to excite the surface of the sample; the element-specific kinetic energies of the resulting emitted Auger electrons are then measured. The Auger Effect is a 3-electron process that works well for lighter elements, with the exception of Hydrogen and Helium that cannot be detected. The produced n/E data is differentiated to reduce the background and then converted into elemental atomic concentration. Because Auger electrons have a very narrow escape depth, AES is a surface sensitive, ultrahigh vacuum technique.

What is a cylindrical mirror analyzer?

The cylindrical mirror analyzer (CMA) consists of two concentric cylinders with entrance and exit slits that allow electrons with an entry angle of 42.3 degrees to pass through a collection aperture and be detected with an electron multiplier. Only electrons with a kinetic energy of approximately 1.7 times the outer cylinder sweep voltage have the correct trajectory required to pass through the collection aperture. Therefore, the CMA is effectively a narrow band kinetic energy filter.

An integrated electron source is used to excite the top few monolayers of the sample being analyzed. The co-axial electron source also greatly simplifies the sample-to-CMA alignment procedure.

s

The CMA is the most prevalent type of analyzer used for AES due to the ease of sample alignment and its high sensitivity.

There are two types of CMAs: imaging and non-imaging. Imaging CMAs incorporate a high spatial resolution electron source and can image small particles at high magnification. Non-imaging CMAs do not incorporate a high spatial resolution electron source and so do not provide imaging capability. Non-imaging CMAs are used primarily for thin film analysis of coatings where imaging of defects is not required.

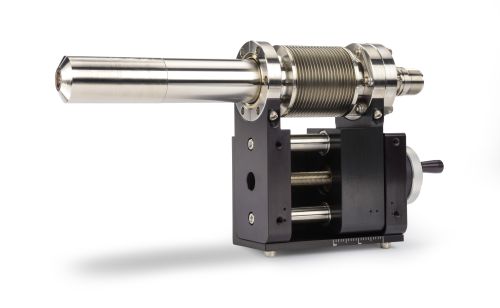

RBD Instruments microCMA (Compact Auger Analyzer) allows you to perform non-imaging Auger Spectroscopy on the your own chamber, for a fraction of the cost of a standalong-system.

What kinds of samples can Auger Spectroscopy analyze?

AES works well on conductive and semi-conductive samples that are ultra-high vacuum compatible.

Elements detected include Li to U (AES cannot detect H or He) with concentrations of at least 0.1 to 1 atomic percent.

What is the ideal use of AES?

AES is ideal for identifying elements or contaminants present on a surface (the top few monolayers) and for determining the atomic concentration of those elements.

What are the limitations of AES?

AES does not work well with nonconductive samples like glass or thick oxides because those types of samples can become charged by the electron beam.

Polymers do not work well for AES because the electron beam can damage the sample.

The minimum detectable concentration limit for AES is typically 1%.

AES is an ultra-high vacuum (UHV) technique, so samples must be UHV compatible.

Electron beam-induced effects can include electron-stimulated desorption and decomposition, beam damage, charging effects, and sample heating. These effects can be minimized by using a low beam current.

How much does an Auger Spectrometer cost?

Dedicated high spatial resolution scanning Auger spectrometer systems can cost well over $1M depending on options such as gas cluster sputter ion sources.

At the far other end of the price range is RBD's very compact microCMA, which costs under $40K. The microCMA analyzer fits on a 2.75" / 70 mm CF flange and can therefore be mounted on an existing vacuum chamber. It is perfect for elemental analysis of thin films and coatings that do not require high special resolution scanning Auger.